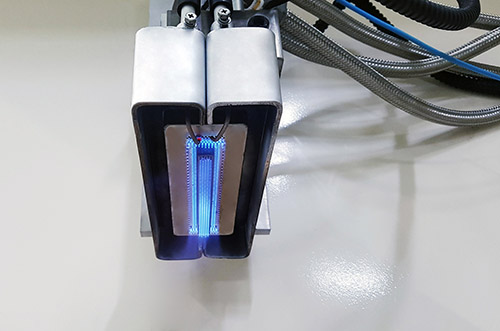

Special Surface Treatment System (Radical Type)

By combusting special organic compound in the flame, it maximizes hydrophilicity, adhesion, printing.

Also, this eco-friendly machine has advantage such as applicable to 3D material, requiring low maintenance fee.

Key Features

- Carbon Radical cam improve the surface which is difficult to apply corona or plasma treatment

∗ Polymer : PP, PE, PET, PBT, FRP, Carbon fiber, Thermosetting resin, Thermoplastic elastic body etc.

∗ Metal : Fe, Stainless steel, Al, Mg, Ti, Zn, Sn etc.

∗ Inorganic material : glass, ceramic, standard inorganic substance etc.

- Longer hydrophilic maintaining period than plasma, corona, UV treatment

- Less maintenance cost and fast speed of surface treatment, 3D material applicable, high efficiency

Specifications

| Parameter | Description / Value |

|---|---|

| Input Power | 3 phase 440V |

| Power Consumption | 5kW |

| Dimension | 1,650 x 1,200 x 1,000 mm |

| Weight | 100 kg |

| Special Solution | The amount used : about 5g/hr |

| LPG | The amount used : about 250~500g/hr |

| Air | Dry Air |

| Material | Steel (SS400) |

| Function | PLC / Alarm / On&Off Signal Communication |

| Warranty | 1 year |

※ The appearance and specification of the product may be changed without prior

notice for the improvement of the product.

※ If do not use dry air, drop the performance.

※ Manufacturer does not offer LPG or Air.

※ Special reagent is consumable and is required to purchase separately.

(1L plastic container)

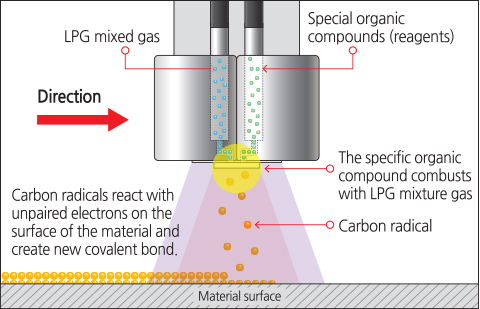

Principle

What is Radical? An unpaired electron

A new concept of surface treatment system increases ‘surface energy’ by making hydrophilic group(C-OH or -COOH) through reaction between ‘stable carbon radical’ generated from flame burner and material surface

hydrophilicity comparison

※ Dyne level of water : 70 and more

Performance comparison by processing method

| Classification | Glass | PP | HDPE | Steel | Al |

|---|---|---|---|---|---|

| Current dyne | 35 | 40 | 38 | 34 | 40 |

| After corona Treat | 35 | 46 | 46 | 34 | 40 |

| After flame Treat | 35 | 52 | 50 | 34 | 46 |

| After SST | 73 | 73 | 73 | 73 | 73 |

Advantage

Applicable for various type of surface treatment

1. Special flame improve to make hydrophilic surface on metal and its alloy, and oxidative surface on metal. (Just only, protective oxidation surface)

2. It improve to make hydrophilic surface on polymers and silicon ompounds without polarity.

3. It improve to make hydrophilic surface on ceramics and glass,

it is difficult other method.

Eco Technology

1. To make hydrophilic surface does not use acid and base. (Excluding washing)

2. To make hydrophilic surface does not use VOC and a dangerous agents. (Volatile Organic Compound)

Improvement of Productivity and cost reduction

1. Very fast speed on surface treatment (30 – 1,000m/min)

2. It is not necessary other apparatus, just Special flame

(Air compressor, LPG gas or LNG gas)

3. Just need Air, Gas and Special solution

The other

1. Extend to use the water coatings, water Inks

2. Remove the Primer process

3. Adhesion among the difference of materials

4. Customize & Sample Test

Application

Adhesion Tech.

1. Adhesion for silicon materials

2. Adhesion for engineering plastics

3. Adhesion for plastics and metals

4. Adhesion for plastics and glasses

Printing Tech.

1. Direct digital printing for plastics

2. Direct digital printing for metals and

glasses (ceramics)

3. Other application : screen, web and

pad printing

Coating Tech.

1. Coating for metal such as Mg, Al, etc

2. Coating for rubber, engineering plastics

3. Free primer coating for PP, PE

4. Coating for inorganic compounds and glass

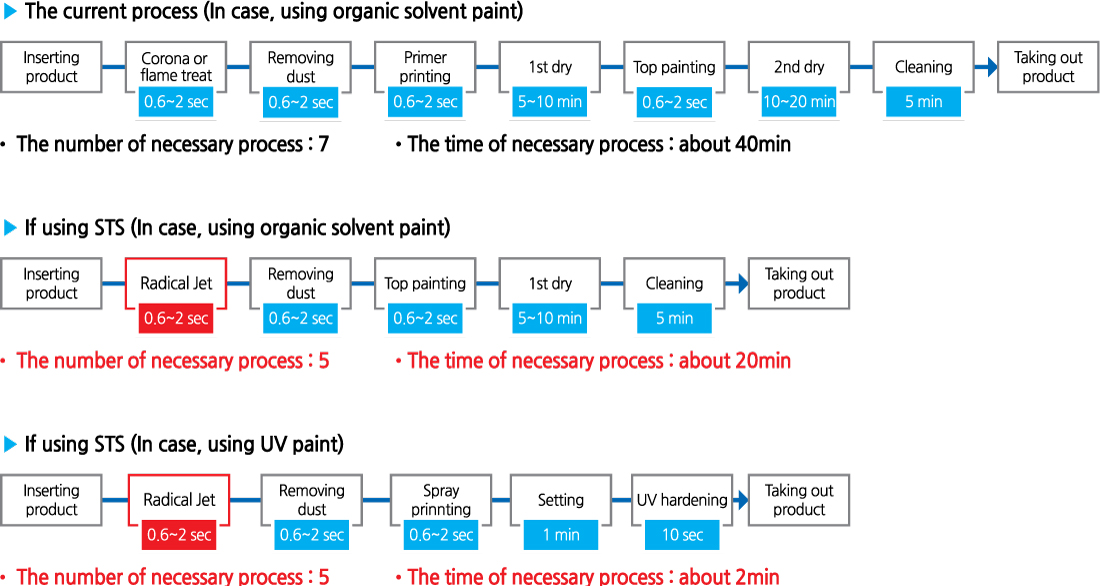

Process